OUR

FACILITIES

PRODUCTION & MOLD DESIGN

We create and produce custom molds for your product needs. From small to big size product, any variety, we give attention to every detail.

PRODUCTION CAPABILITIES

We are using the latest technology for every inch of our products. Giving you the most advanced precision on the line.

PREFORM MOLD

We are using the latest technology for every inch of our products. Giving you the most advanced precision on the line.

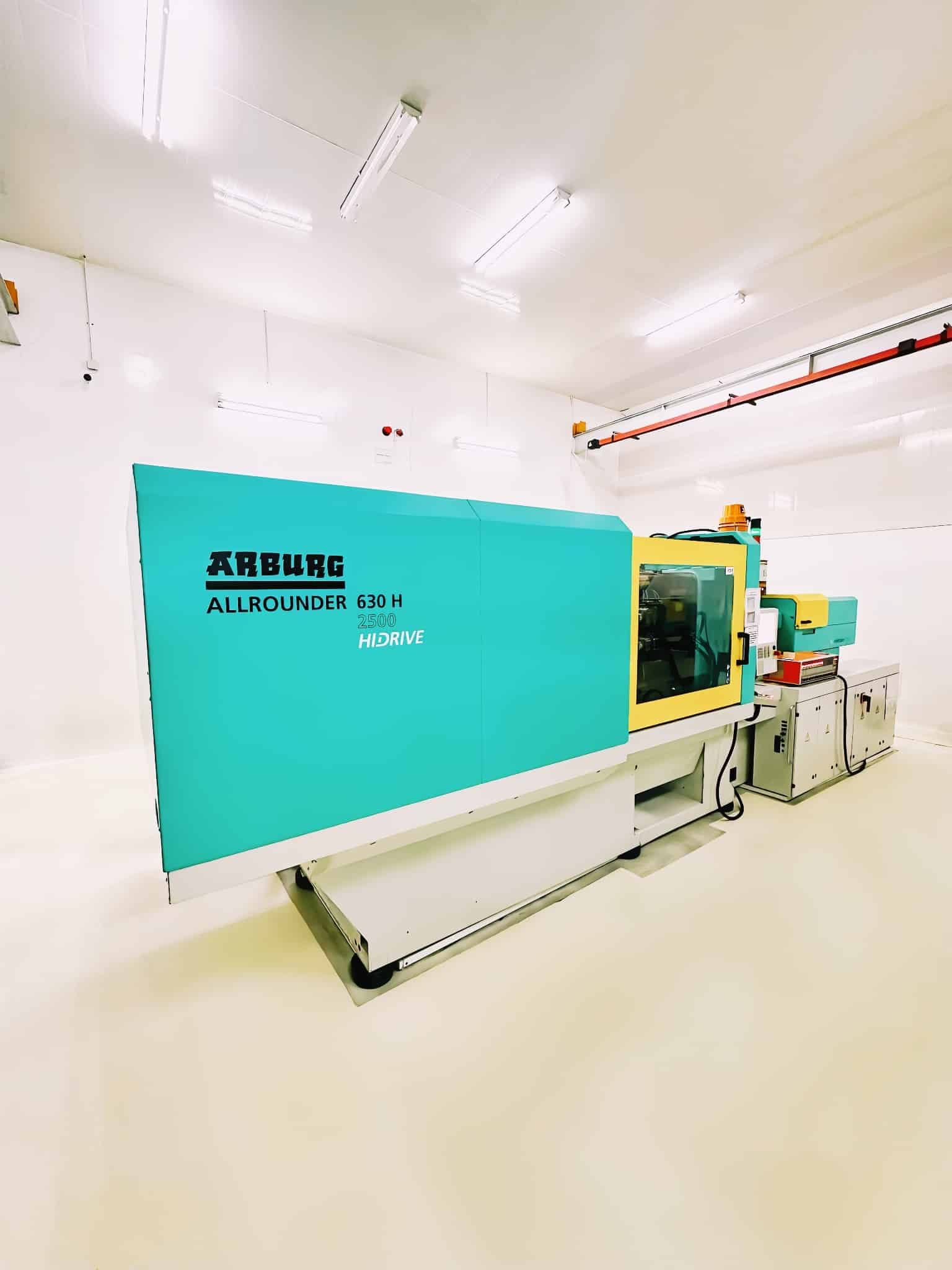

PRODUCTION MACHINES

We also have many kinds of machine variety to make sure your products are delivered safely to you.

HYGIENE ROOM

We also make sure a clean procedure was performed from our operators and machines, therefore we standardize our production with FSSC 22000 standard

IN-MOLD LABELING SYSTEM

We use the IML (In-Mold Labeling) system to directly attach labels to finished good products, improve time efficiency and product cleanliness.

TWO-COLOR

Also we can make you a two color injection product, such as gallon cap. Available with different kinds of colors to be selected.

HI-SHEET / INDUCTION SEAL ASSEMBLY

We make sure every product are delivered carefully and unbreakable. We use the latest technology to seal your product.

WAREHOUSE RAW MATERIAL

Every raw material that we use will be handled carefully to make sure the later processes are going smoothly.

OTHER FACILITIES

And all of that high-technology will be supported with some other facilities that give you the best experience.